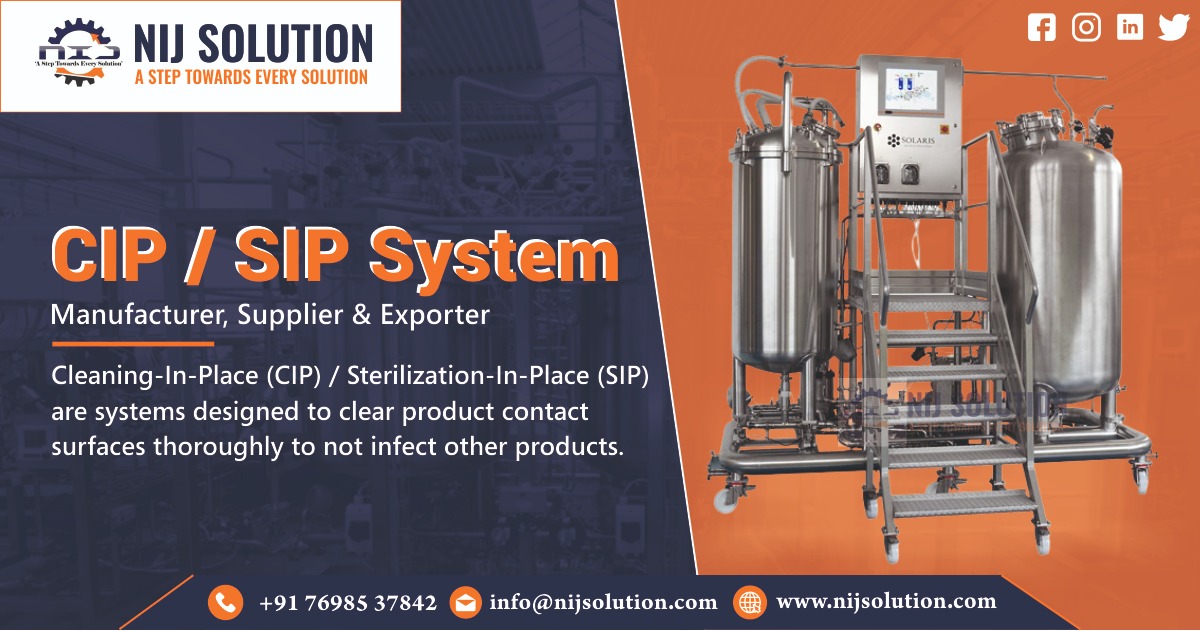

CIP/SIP System Exporter in Kenya:

Manufacturer of CIP/SIP Systems in Ahmedabad: Systems such as cleaning-in-place (CIP) and sterilization-in-place (SIP) are made to properly clean product contact surfaces in order to stop the contamination of other products.

What Can Nij Solution Provide?

Skid-mounted SIP/CIP systems are produced by NIJ SOLUTION and come with all of the necessary components for cleaning existing pipelines, vessels, or process equipment. These components include a sanitary pump, tank (if necessary), valves, sensors, and pipes, and they can be automated using a PLC or electrical panel.

Systems like Clean-in-Place (CIP) and Sterilize-in-Place (SIP) are made to automate necessary cleaning and disinfection tasks rather than requiring time-consuming installation and disassembly. Cleaning needs to be done effectively and efficiently if a process is to be optimised. All of GEA’s pharmaceutical machinery, including systems for solid and liquid dosage formulation, is CIP system compatible.

Cleaning-in-place (CIP) and sterilization-in-place (SIP) system specifications are as follows:

Heating method: with Industrial Steam and/or Electrical Heater.

MOC: Stainless Steel 304, 304L, 316, 316L.

Capacity: 5 L to 10 L

User segments: Pharmaceuticals, Petrochemicals, Dairies, and Food & Beverages Industries.

If you need a CIP/SIP System Exporter in Kenya Including Baragoi, Bungoma, Busia, Hola, Isiolo, Kissil, Kitui, Kajiado, Kukuma, Keroka, Kilifi, Lamu, Langata, Lodwar, Meru, Moyale, Mombasa, Mumias, Nairobi, Nakuru, Narok, Nyeri, Thika, Voi, Wajir, Watamu, Wote, Wundanyi