CIP (Clean-in-Place) Systems and Design. Cleaning in place (CIP) is a method of cleaning sanitary process lines, vessels, and equipment in process facilities. Clean-in-place (CIP) is a method of removing product soils by running a cleaning fluid across a surface.

Sterilization in Place is the process of sterilizing production equipment without disassembling it first. The most common method of sterilization is to use superheated steam. SIP systems are utilized in environments where germ minimization is critical. Biotechnology and the food sector are two examples.

NIJ SOLUTION manufactures skid-mounted SIP/CIP systems that include all necessary equipment such as sanitary pump, tank (if required), valves, sensors, and necessary piping for the purpose of cleaning existing piping, vessels, or process equipment with or without automation via a PCL or electrical panel.

Specification:

Heating method: with Industrial Steam and/or Electrical Heater.

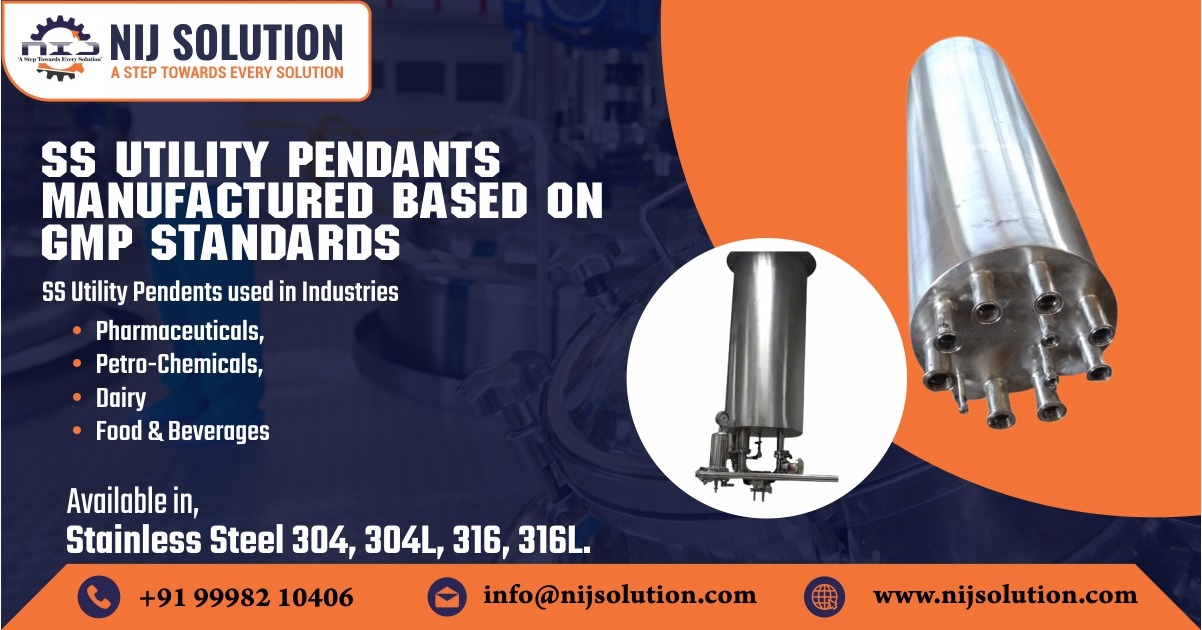

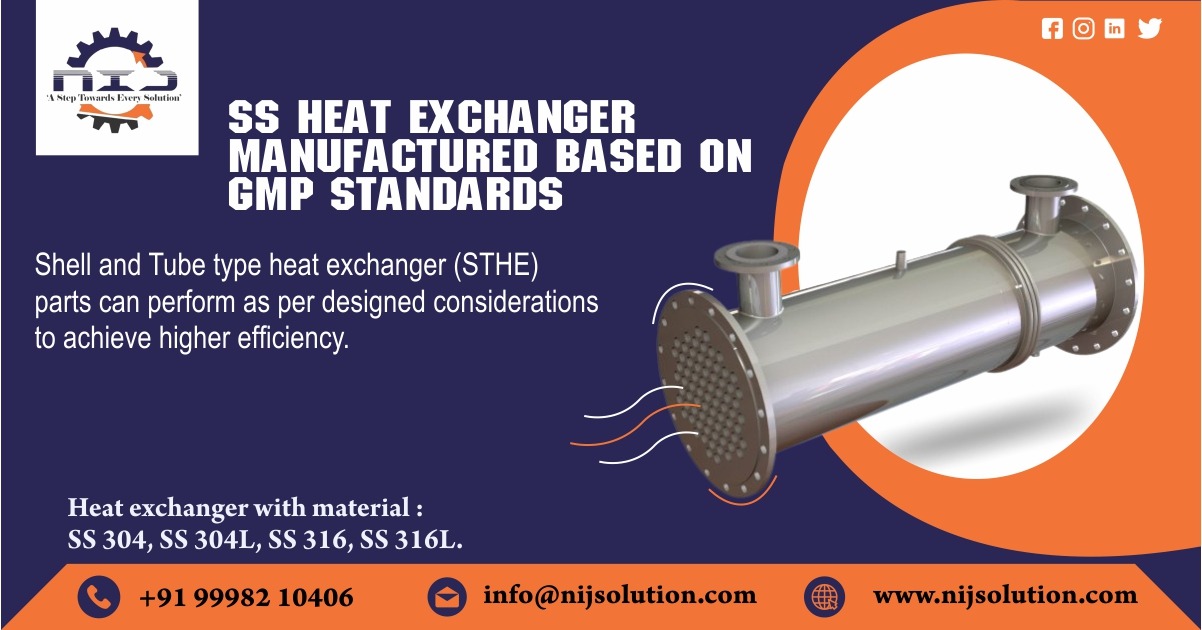

MOC: Stainless Steel 304, 304L, 316, 316L.

Capacity: 5 L to 10 KL

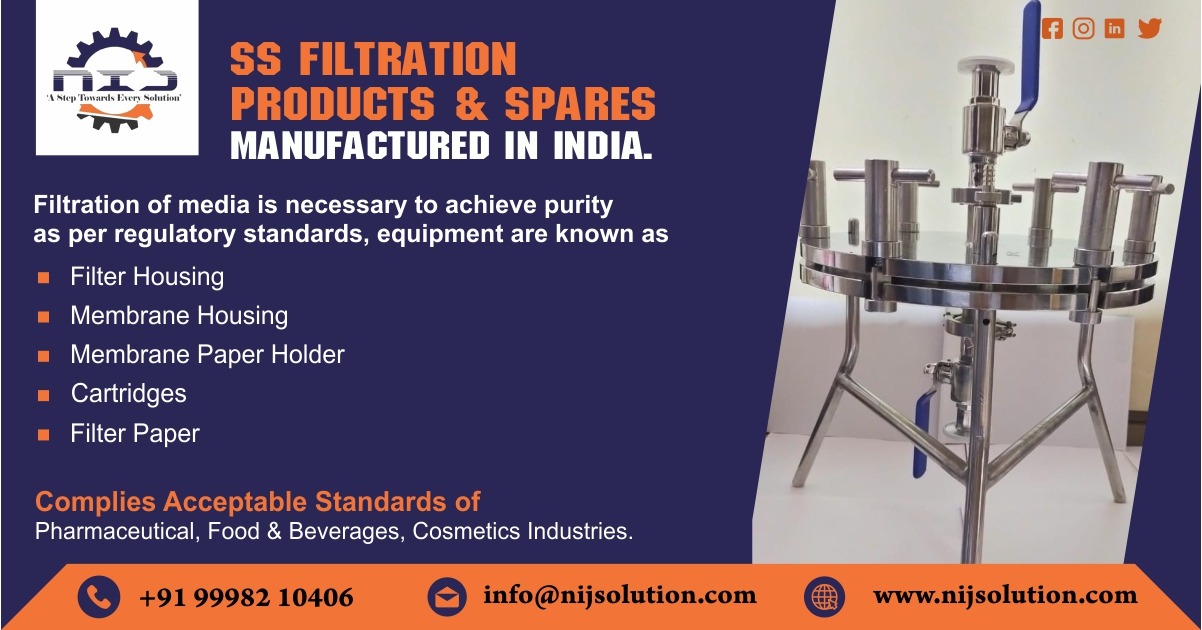

User segments: Pharmaceuticals, Petro-Chemicals, Dairies and Food & Beverages Industries

Make : NIJ

Clean-in-Place (CIP) systems can be incorporated into all the equipment produced by GEA for the pharmaceutical industry, including both solid and liquid dosage formulation systems.

For more information on CIP/SIP System kindly contact us at below details:

Nij Solution

Call Us : +91 7698537842

Email Us: info@nijsolution.com